_1.jpg)

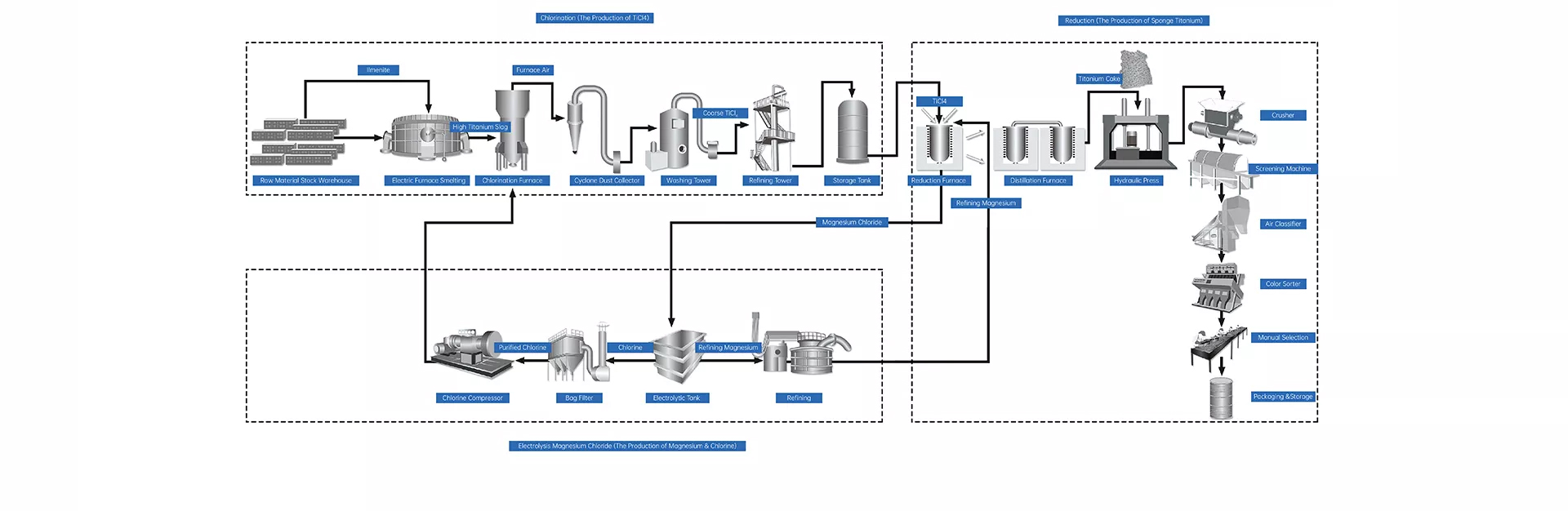

Jinda's flagship product high-uniform, high-purity, and high-stabiity titanium sponge, remains a central focus. The titanium sponge ismanufactured utlizing the "kroll rocess", a thermal reduction technique involving magnesium. In the subsequent distilation phase, meticulouscontrol is exercised to achieve nearly negligible impurity levels.

_bg.png)

_title.png)

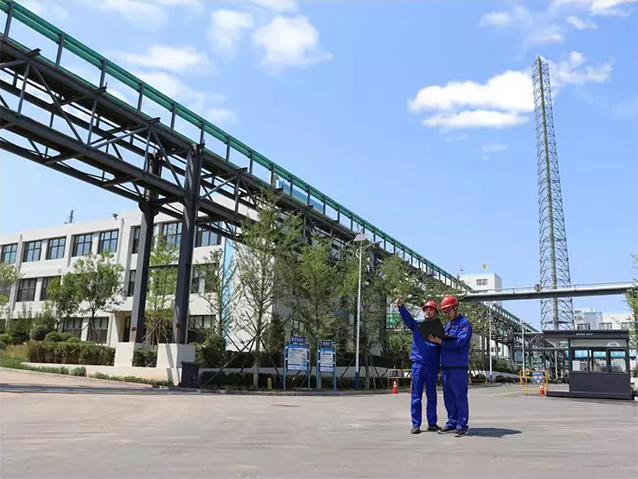

1.Jinda commits to delivering exceptional products and maintaining a reliable supply capacity.

2.Jjinda has pioneered the creation of a cutting-edge crushing-selection production line for titanium sponge

3.The first-class, independently designed production ine guarantees the quality of the titanium sponge, ensuring impeccable appearance and acomplete absence of forein substance.

_1.jpg)

Jinda has taken strategic steps to ensure the quality of raw materials and process control which includes the establishment of a titaniumtetrachloride production line, employing Chind's most advanced technology. The comprehensive process encompasses feeding of titanium slacand rutle , which would be experienced chlorination and refining. As a result of this process, chlorine is transformed into refined titaniumtetrachloride, which serves as the primary raw material for producing titanium sponge.

.webp)

.webp)